FuruizeCup

Introduction

The menstrual cup market has surged in recent years, driven by eco-conscious consumers and health-focused innovations. However, manufacturing these intimate healthcare devices demands strict adherence to global compliance standards. This article explores key regulatory frameworks, certifications, and quality control measures essential for producing safe, compliant menstrual cups.

1.Understanding Regulatory Classifications

Menstrual cups are classified as medical devices in many regions. For example:

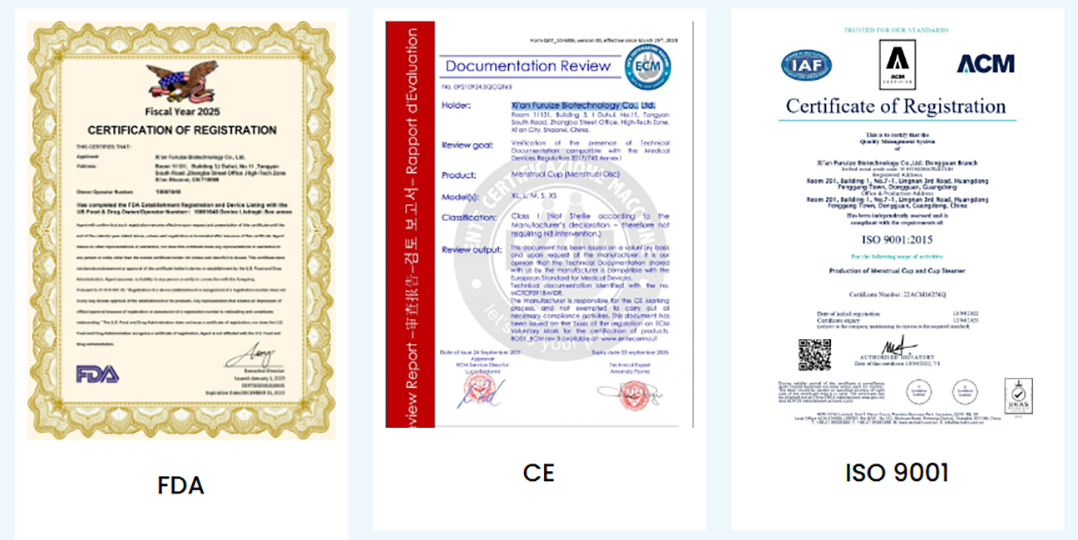

FDA (U.S.): Class II medical devices requiring premarket notification (510(k)) to demonstrate safety and equivalence to existing products.

EU MDR (Europe): Class IIa or IIb devices under the Medical Device Regulation, requiring CE certification through rigorous clinical evaluations and post-market surveillance.

Other Markets: Countries like Canada (Health Canada), Australia (TGA), and Japan (PMDA) have similar classifications, often mandating biocompatibility testing and sterilization validation.

Compliance starts with understanding jurisdictional requirements to avoid costly recalls or market entry barriers.

2.Material Safety and Biocompatibility

Menstrual cups must use medical-grade materials to prevent toxicity or allergic reactions. Key considerations include:

Silicone Compliance: Most cups use platinum-cured silicone, which must meet ISO 10993 standards for biological safety (e.g., cytotoxicity, irritation, and sensitization tests).

Additive-Free Manufacturing: Ensure no phthalates, BPA, or latex are present, aligning with REACH (EU) and Proposition 65 (California) regulations.

Sterilization Validation: Ethylene oxide (EtO) or gamma radiation processes must comply with ISO 11135 or ISO 11137 standards.

3.Quality Management Systems (QMS)

Implementing a robust QMS is non-negotiable for compliance:

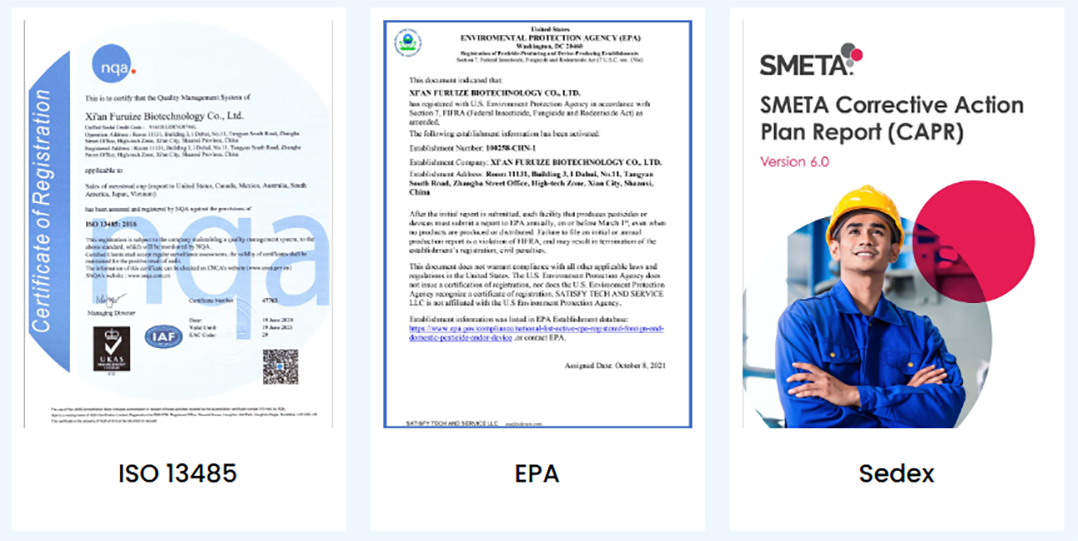

ISO 13485 Certification: This standard specifies requirements for a QMS in medical device manufacturing, covering design controls, risk management (ISO 14971), and traceability.

Good Manufacturing Practices (GMP): Adhere to FDA 21 CFR Part 820 or EU Annex 11 guidelines for facility hygiene, documentation, and batch testing.

Supplier Audits: Ensure raw material suppliers (e.g., silicone providers) meet ISO 9001 or equivalent standards.

4.Sustainability and Ethical Compliance

Modern consumers demand eco-friendly practices:

Recyclability: Certify products via programs like TÜV Austria’s OK compost INDUSTRIAL for industrial compostability.

Ethical Labor Practices: Align with SA8000 or B Corp certification to ensure fair wages and safe working conditions.

Conclusion

Navigating menstrual cup manufacturing compliance requires a proactive approach to regulations, material science, and ethical practices. By prioritizing certifications like FDA, CE, and ISO 13485, brands can build trust, reduce risks, and capitalize on the growing demand for sustainable feminine care solutions.

FURUIZE

Share this entry

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

Click here to add your own text